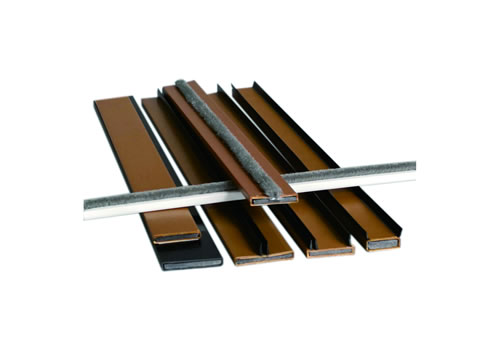

| Developing process | Description | Advantage / Disadvantage |

| 1st Generation | Extrude core & case separately, thread the core and put adhesive tape manually | Tolerance is so difficult to control that easily lose the core. Many procedures cause the surface of case to be demaged. |

| Punch the point at on side of case, in order to hold core tightly | Cause the case deformation | |

Produce core, case, pile or flipper separately, Threading the core and pile and flipper manually | Tolerance is so difficult to control that easily lose the core. The pile and flipper easy to pull out. | |

| 2nd Generation | The core and case are co-extruded at one time | Does not fall off |

| 3th Generation | Put adhesive tape automatically | Neat and efficient |

| 4th Generation | Threading pile automatically | The pile easy to pull out sometimes |

| 5th Generation | Upgrade of threading pile | Pile does not pull out by strength at length of 150mm |

| 6th Generation | The core ,case and flipper are triple-extruded at one time | The core and flipper do not fall off |

| 7th Generation | Upgrade of flipper for thinner & tearing resistance | Thin flipper (0.4mm) cannot be torn |

| 8th Generation | Laser printing logo and production batch numbers automatically | Print logo and production batch numbers for customer |